Drive Over Scales

Weighs vehicles while in motion – without having to stop!

WeighbridgeSmart

Heavy-Duty Drive Over Scales: Agreto Drive Over Scale 3.4 X 1M

Drive Over Truck Scales by WeighbridgeSmart

Drive over scales weigh vehicles while in motion – without having to stop!

- Easy to install, easy to operate

- Makes unmanned weighing possible during harvesting

- Weighs axles up to 15 tonnes

- Platform size is 3.4 x 1 m

- Cost effective alternative for significantly more expensive weighbridges

- Ideal for agriculture and biogas plants, or used as an axle load scale in trade and industry.

Inexpensive drive over truck scales

The AGRETO drive-over-scale is the most cost effective way for weighing trucks and agricultural vehicles without limitation.

Robust and practical

The weighing platform is galvanized and has a carrying capacity of 15 t per axle. The scale is waterproof and 4 weighing cells with a 10 t nominal load each ensure it’s overloadproof as well.

Automatic weighing while in motion

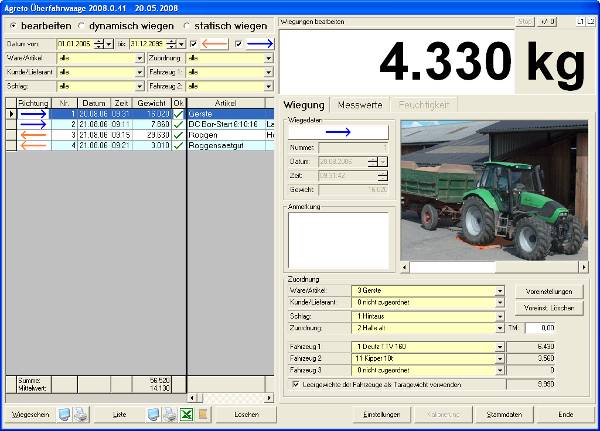

The AGRETO drive-over-scale weighs the axle load of several vehicles that move over the platform. Axle loads are automatically added to calculate total weight. You don’t have to stand still or get out of your vehicle, and you don’t need extra personnel like you do with a weighbridge. PC software automatically logs all weighing data.

Reliable axle recognition

The AGRETO drive-over-scale’s light barrier system identifies tyre size, wheelbase, driving direction and driving speed. This enables exact and error-free weighing of large tractor rear tyres, as well as all axle combinations (tandem, tridem axles).

Control Your Drive Over Scales With PC Software or Weighing Terminal

Optionally, the AGRETO over-ride scale can be operated with the new AGRETO weighing terminal or with a PC and the PC software. Please select as accessory either the terminal or the software control.

Technical Data

Delivery contents:

- 1 weighing platform with electronics box, weighing equipment and legs

- 10 m connecting cable for PC, with plug and power supply unit

- 1 USB-RS232 converter

- 1 construction manual with foundation plan and reinforcement plan

- 1 User manual

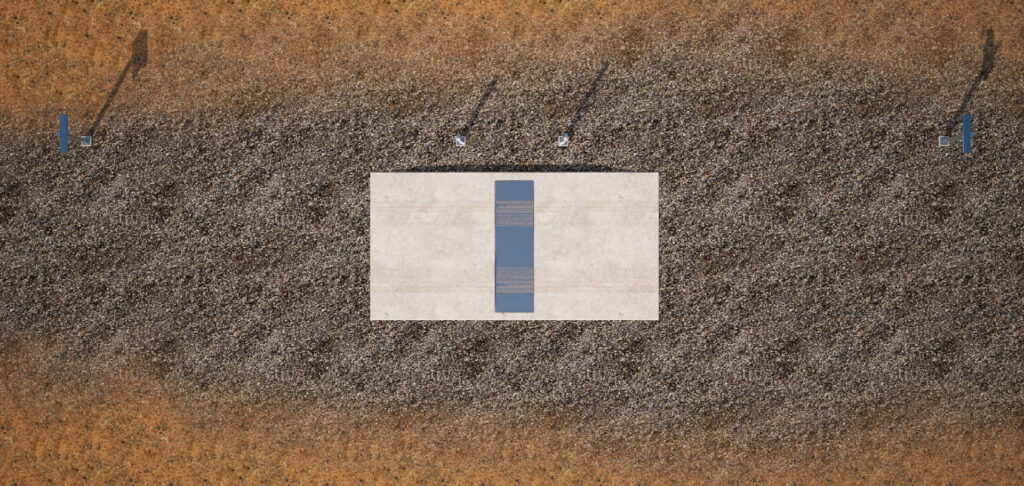

Weighing platform:

- Galvanized steel construction made of 3 robust I-beams and reinforcing elements

- 2 side panels for load cell mounting

- Antiskid checker plate cover with maintenance cap

- Platform size: 100 cm x 340 cm

- Welded protective housing for the light barriers

Load cells:

- 4 high-resolution shear force load cells made from tool steel

- 10 t nominal load per cell, 150% secure overload = 15 t, 300% breaking load = 30 t

- 5-12 Volt power supply, 350 Ohm resistance

- Waterproof according to protection class IP68

- 2 x M27 mounting screws, suspension for load foot

- Dimensions: 60 x 67 x 279 mm

- Operating temperature -35 to +65 °C

- Temperature compensated -10 to + 40 °C

Electronics:

- Waterproof electronics box under the maintenance cap of the weighing platform

- A/D-converter with serial data transfer to the PC

- Connecting terminals for 4 weighing cells and 2 light barrier pairs

- Screw plug for hooking up the connecting cable to the PC

- 5-pole shielded connecting cable to the PC for data transfer and power supply

- 10 m standard cable length, extensible up to 100 m

- 24 Volt transformer power supply unit for a reliable power supply

Installation requirements:

When choosing a location for your drive over scales, make sure that the area for approaching and exiting the scale is as even as possible, for the entire length of the vehicles that need to be weighed (30 to 32 m in total for semi-trailer trucks). Ideally this roadway is level in all directions. A slight slope to the side or upwards in the driving direction is acceptable, when this slope is exactly the same everywhere on approach, scale and exit. For weighing multiple axles we advise the construction of a concrete slab at least 3 m before and after the weighing platform. The approach and exit are essential parts of the scale and must be constructed with care. In practice, proper installation and use will guarantee only minimal deviations from a calibrated weighbridge.

Frequently Asked Questions

How does the AGRETO drive-over-scale function?

The AGRETO drive-over-scale weighs vehicles dynamically while in motion. Weighings are automatically registered and stored on your PC.

Do I have to stand still on the platform with each axle?

Generally speaking, no. The AGRETO drive-over-scale is designed for dynamic weigh-in-motion. Axles are automatically weighed one after the other. Only when you weigh liquid containers or barrels that aren’t completely full, do you need to weigh statically, ie stand still on the platform with each axle. The software contains a separate mode for that.

How fast can I cross the scale?

You have to drive at walking speed. The best results are obtained when driving 2 to 4 km/h with agricultural vehicles, and 4 to 6 km/h with trucks. The AGRETO drive-over-scale monitors your driving speed and issues a warning when a weighing isn’t optimal due to too much speed.

Do I have to specify the amount of axles up front?

No, not at all. The AGRETO drive-over-scale software automatically registers the amount of axles.

What are the advantages when compared to the AGRETO do-it-yourself drive-over-scale?

- The “big” AGRETO drive-over-scale is controlled by PC software. This software doesn’t just manage data, but also monitors and assures the quality of weighings. All the usual vehicle scale accessories, like outdoor displays, remote control, traffic light signalling, image processing and protocol printers and log printers can be delivered.

- The platform has a length of 100 cm (in the driving direction). This is the only way one can weigh large tractor rear tyres.

- The platform is equipped with a light barrier system. This enables the recognition of driving direction, driving speed, tyre size, wheelbase and the overlapping of axles on the platform. These functions turn an axle load scale into a reliable vehicle scale.

What does a dynamic weighing look like?

You simply drive your vehicle over the scale. The weighing procedure is started automatically as soon as the first axle applies a load to the platform. 60 weighing points per second are made while the axle crosses the platform. These enable the software to calculate axle weight. When the axle leaves the platform, the pre-set waiting time starts (for instance, 10 seconds). A new weighing procedure starts if within that time another axle crosses the platform. When this doesn’t happen, the weighing procedure ends, and total vehicle weight is calculated and logged.

What does a static weighing look like?

During a static weighing every axle stands still on the platform. The software contains a separate mode for this. When applied, the large display signals whether an axle is situated in the middle of the platform, at what point axle load is stable and whether motion can be resumed. After the last axle and subsequent waiting period the weighing procedure ends, and total vehicle weight is calculated and logged.

What happens when 2 axles stand on the platform at the same time?

With vehicles with multiple axles and a narrow wheelbase it could occur that the first axle is still on the platform when the second axle enters it. This situation isn’t a problem for the AGRETO drive-over-scale. The light barrier system locates the exact position of the axles and determines whether an axle can be weighed or not. As soon as a second axle enters the platform, weighing of the first axle is stopped.

Why is the AGRETO drive-over-scale platform 1 m long in the driving direction?

For weighing trucks a smaller platform would be sufficient. For agricultural vehicles however, the tractor must be included in the weighing because of high vertical loads. This makes a 1 m long platform a prerequisite. Large low pressure tyres can have a wheel contact surface of up to 90 cm under load. On top of that, a larger platform enables the AGRETO drive-over-scale light barrier system to optimize the quality of weighings. All axles are weighed for as long as possible, depending on the contact area.

Is the AGRETO drive-over-scale calibratable?

A calibrated weighing for legal transactions can only be produced by a scale on which a vehicle can stand in its entirety. Axle by axle weighing cannot produce a calibrated total vehicle weight. The AGRETO drive-over-scale is used as a checkweigher for internal use. One advantage is that there aren’t any calibration costs.

How accurately does the AGRETO drive-over-scale weigh?

The built-in load cells have an accuracy of 0.02% and can be calibrated. Axle weight is calculated in 1 kg increments, total vehicle weight in 10 kg increments. The scale’s accuracy is essentially higher than that of a weighbridge. The decisive factor, however, is the roadway in front of and behind the scale. In practice, proper installation and use will guarantee only minimal deviations from a calibrated weighbridge.

How is the AGRETO drive-over-scale constructed?

The weighing platform must be built into a foundation that is constructed on site. You receive plans and detailed installation instructions for building the foundation and installing the platform. A prefabricated foundation isn’t an option due to high transportation costs.

What is the scale’s ideal location?

The scale should ideally be positioned in such a way that vehicles that need to be weighed, pass there anyway when leaving or entering the farm. Of course, the terrain has to be suited for the construction of a drive-over-scale. The possibility of regular traffic driving over the scale should be avoided. Although this won’t damage the scale, it will get dirty faster and every crossing is registered if the software is active.

What does the roadway before and after the scale have to look like?

When choosing a location for your scale, make sure that the area for approaching and exiting the scale is as even as possible, for the entire length of the vehicles that need to be weighed (30 to 32 m in total for semi-trailer trucks). Ideally this roadway is level in all directions. A slight slope to the side or upwards in the driving direction is acceptable, when this slope is exactly the same everywhere on approach, scale and exit. For weighing multiple axles we advise the construction of a concrete slab at least 3 m before and after the weighing platform. The approach and exit are essential parts of the scale and must be constructed with care.